Ripple Voltage Injection May Cause LED Lights to Flicker

In some parts of Australia power lines are injected with a ripple voltage, or pulse. This can be at a frequency ranging from 167Hz to 1050Hz and is also known as the Zellweger ripple or audio frequency injection control (AFIC).

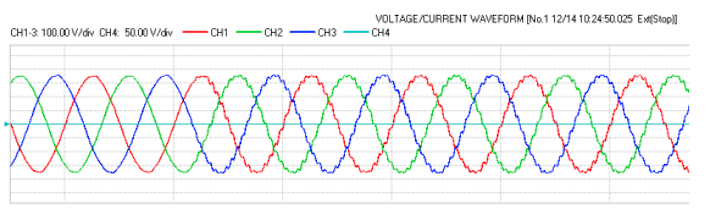

The below image shows the impact of a 1050 Hz signal with a magnitude of approximately 6V (2.6% of 230 V) on a waveform measured in the field. The injection signal can be seen to commence approximately 1.5 cycles after the start of the waveform capture.

The purpose of this ripple voltage injection is to provide a signal that can remotely switch smart equipment, such as hot water heaters and streetlights, either to take advantage of off-peak power rates, or to be switched on/off at a specific time.

Ripple voltage injection is a low-cost method of providing one way communication as no additional communications infrastructure is required.

The ripple voltage that is injected may cause problems with various appliances or electronic equipment, one example being light fittings. This can be incandescent or LED lighting. The issue appears to be becoming more prevalent with the increasing use of LED lighting and advanced electronic dimmer controllers.

Modern LED lighting installations add a level of complexity to a lighting system. In some instances, waveform distortion caused by ripple injection signaling, will lead to some LED lighting systems producing anything from a subtle flicker through to strobing.

If the LED lights are flickering within a similar time window each day, then it could be a ripple voltage injection that is the cause. The ripple may only be present for a few seconds or tens of minutes.

Not all LED lights are affected by ripple voltage injection, some combinations of LED chips and LED drivers appear to be immune to the ripple injection signal while others are highly susceptible.

There are two possible methods to solve the problem.

One solution is to try different LED driver / LED combinations. It is recommended that you try one location first and only when you have a working combination do you go on to replace all the other LED drivers in an installation. It should be noted that if a certain combination is affected by ripple voltage injection it is not considered to be a failure under the LED driver warranty.

Customers are asked to contact ADM before removing LED drivers for return.

The other remedy is fitting a Zellweger tone filter into the system. You will need to ensure that the model you select is tuned to the frequency of the control signal in use. IE: 750Hz or 1050Hz. However, such filters must be installed and used correctly. Otherwise, they could interfere with normal operation of the ripple injection signals, potentially resulting in the incorrect operation of off-peak hot water heaters.

Ripple injection signaling remains an important part of network operation and will not be phased out soon. Although there is some speculation that with the roll out of smart metering infrastructure, there may be no need in the future for ripple injection control systems.

ADM does not supply Zellweger tone filters but is happy to put customers in touch with reputable suppliers if required.

IS THIS INFORMATION USEFUL?

If so, why not share it with your peers and colleagues. Simply click on the blue LinkedIn share icon below.